Search This Supplers Products:Printing and Packing Machinery

Automatic High Speed 4&6 Corner Folding and Gluing Machine

- group name

- Carton Box Folding And Gluing Machine

- Min Order

- 1 set

- brand name

- WITY

- model

- SHH-FS

- payment method

- L/C, Western Union, T/T, Paypal

- update time

- Mon, 09 Sep 2019 19:20:39 GMT

Packging & Delivery

-

Min Order1 set

Briefing

Detailed

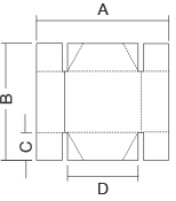

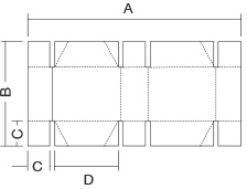

SHH-FS Series folder and gluer is suitable for production of straight line box, bottom locked box, double edge glued box,4&6 corner box.

1. IT adapts the Electrical Plate Adjustment, Delta PLC and foreign famous brand electronic components.

2. The feeding section is controlled by separate motor, rail guide convey, reliable performance and easy operation.

3. The machine is specifically aimed at corrugated carton, its correction function makes corrugated carton more perfect. (We can do customization according to your samples)

|

Model

|

SHH1050FS/1250FS/1450FS/1650Fs/1850FS

|

|

Paper Material

|

A/B/C/E/F Corrugated, 200-800gsm cardboard

|

|

Max.Liner Sped

|

260m/min

|

|

Feeding Way

|

Auto and continuously feeding

|

Way of folding in reverse | Fold 1 and fold 3 are 180°and 135° Fold 2 and fold 4 are 180° |

Glue Material | Water-base cold glue |

Electric power | 14KW 380V 50HZ 3P |

Weight | 9T/9.5T/10T/10.5T/11T |

Over dimension | 16*1.7*1.7m/16*1.9*1.7m/16*2.1*1.7m/16*2.3*1.7m/16*2.5*1.7m |

|

Model

|

1050FS | 1250FS | 1450FS | 1650FS |

1850FS

|

|

A

|

290-1000 | 290-1200 | 290-1400 | 290-1600 |

290-1800

|

|

B

|

130-800 | 130-800 | 130-800 | 130-800 |

130-800

|

|

C

|

Min 30mm | Min 30mm | Min 30mm | Min 30mm |

Min 30mm

|

|

D

|

Min 130mm | Min 130mm | Min 130mm | Min 130mm |

Min 130mm

|

|

Model

|

1050FS | 1250FS | 1450FS | 1650FS |

1850FS

|

|

A

|

290-1000 | 290-1200 | 290-1400 | 290-1600 |

290-1800

|

|

B

|

130-800 | 130-800 | 130-800 | 130-800 |

130-800

|

|

C

|

Min 30mm | Min 30mm | Min 30mm | Min 30mm |

Min 30mm

|

|

D

|

Min 130mm | Min 130mm | Min 130mm | Min 130mm |

Min 130mm

|

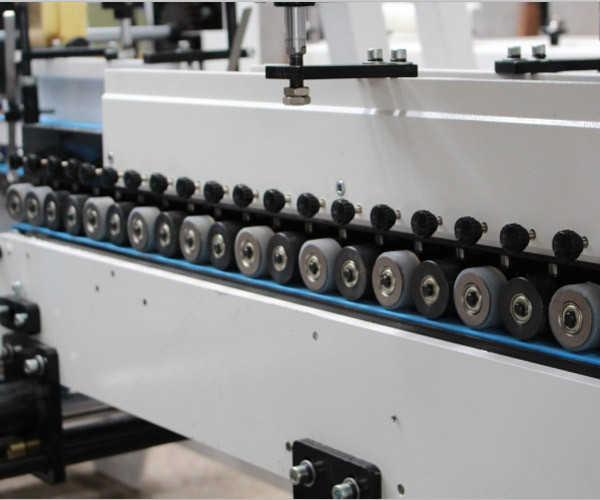

Adjustable feeding belts to ensure easy adjustment, stable and smoothly feeding.

Continuously Variable Speeder to ensure feeding internal and stable transmission.

One-touch Pneumatic knife, easy for the adjustment of feeding belts.

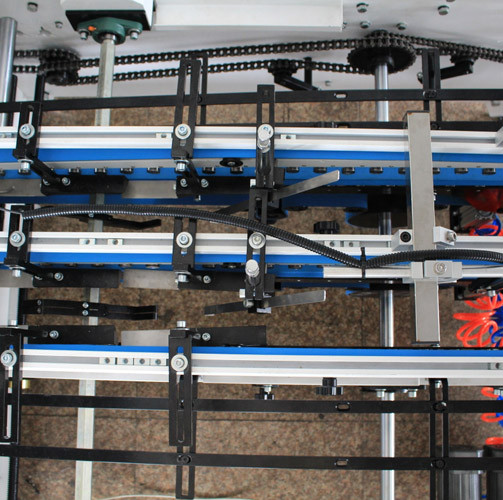

Aligning section, to ensure the carton array correctly for next folding process.

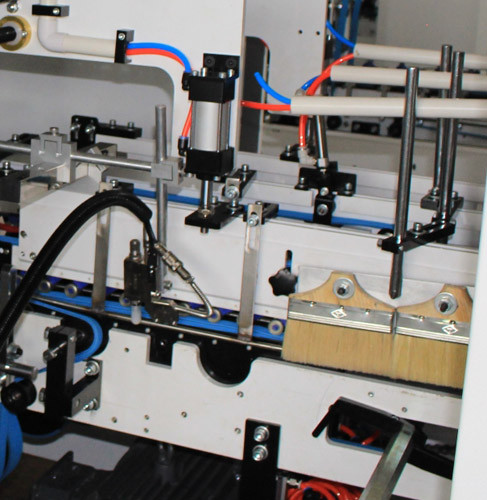

Pre-fold and back-folding section: Equipped with right/ left pre-fold to make 180° pre-folding of tiny flap. Equipped with right/left to make 135°pre-folding (depends on box size), so as to easily unfold.

Bottom Gluing section: All gluing pots can be loaded and unloaded; Two upper gluing pots (right and left) and two lower gluing pots (right and left), could use either upper or lower pots on demand.

Lengthened folding to avoid the unevenness while the rapid forming of cartons and make it come to perfection.

Pre-pressing section: Adopts continuous and automatic box collecting mechanism to ensure boxes enter the Conveyer section neat and well aligned; Equipped with electronic counter/automatic mark spraying kick plate for counting and mark-spraying purposes; Equipped with air compressor system and creasing channel system; Pressure rollers can be adjusted depending on box types and paper quality to achieve flawless box creasing.

Equipped with feeding paper inspection device.

Equipped with impacting device to press the paper after accounting and make it easy to pack paper.