Search This Supplers Products:Printing and Packing Machinery

Automatic Flat Die Cutting Machine

- group name

- Cardboard Die Cutting Machine

- Min Order

- 1 set

- brand name

- WITY

- model

- BL

- payment method

- L/C, Western Union, T/T, Paypal

- update time

- Wed, 11 Sep 2019 18:19:56 GMT

Packging & Delivery

-

Min Order1 set

Briefing

Detailed

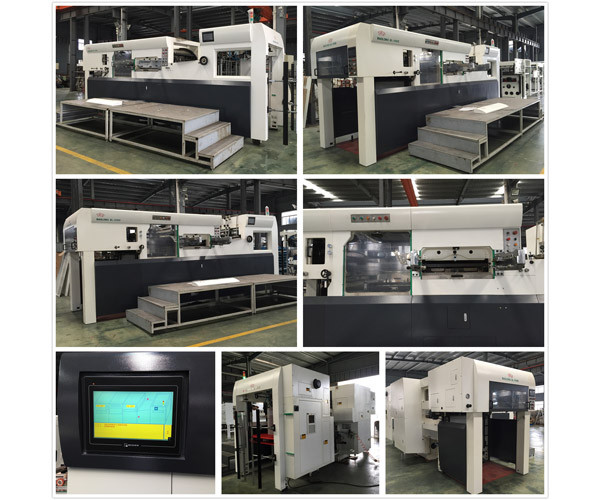

BL-1050 series flatbed die-cutting with stripping is an ideal equipment to die cut and crease the paper, paper board packing material.

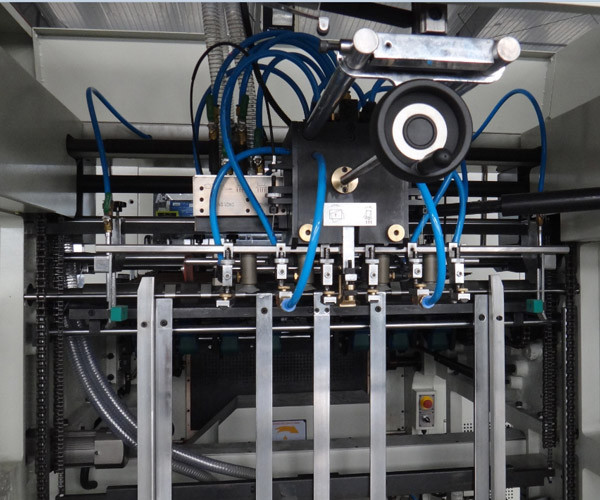

1) It is easy to operate the machine with man-machine interface which automatically displaying the breakdown and frame locking system, digital displaying up-down of mould pressing .

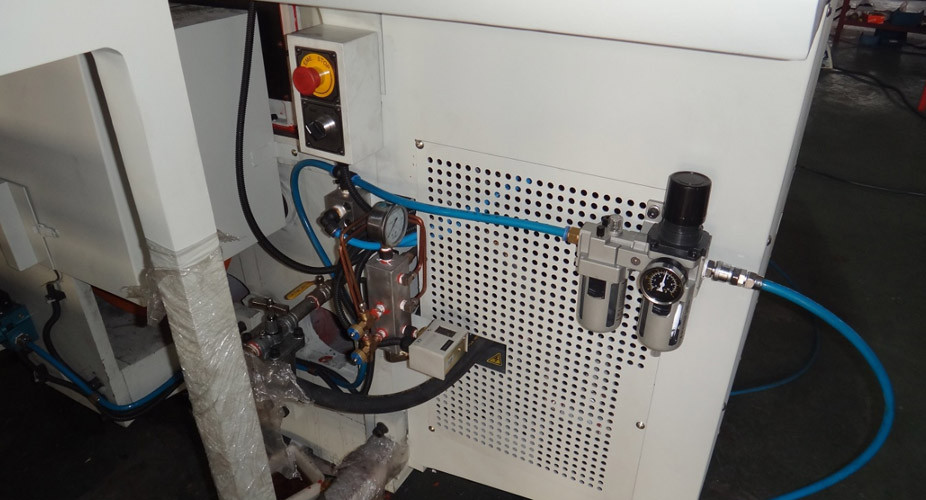

The cooling system of oil circulation decrease difference of hot and cold part of machine so as to reduce the number of rejects and extend the machine service life.

Main electrical components are all world0wide famous brands,

4)Industry cooling system ensure the electric component durable and steady performance.

1. It mainly suitable for high accuracy die cut requirement material such as 0.1~2mm cardboard, corrugated board ≤4mm

2. It is fast working speed, high safety, easy operation

3. It can stable feeding, die cutting and collecting the thin paper which thickness above 80gsm.

4. The feeder with 4 suction and 4 feeding makes paper feeding more smooth

5. Fully automatic non-stop paper feeding and stacking trolley improved the productivity.

6. With die cutting frame automatic lock design, high safety and convenient and simple operating.

7. Die cutting frame high strength and precision, frame backing plate adopt hard stainless steel, beautiful and durable.

8. Die cutting pad plate hardness HRC50~53, flatten and rusty proof, durable using.

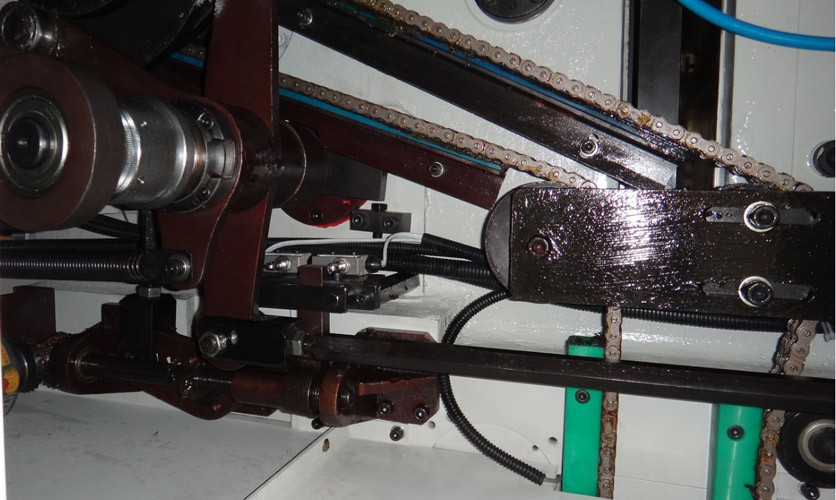

9. Crank shaft, pendulum shaft, worm, etc are all imported alloy steel and precision finishing

10. Oil circulation cooling system improved the difference between heat part and cold part of machine, decrease the rejects number and extend the parts service life.

11. Die cutting lift and backward adopt digital displaying, accuracy 0.001mm

12. Luxury appearance, acheived international standard

Specifications

|

Model |

BL1050S/E

|

|

Max. Paper size |

1050x750mm |

|

Min. Paper size |

400x360mm |

Max. Die cutting size | 1040x720mm |

Die cutting plate size | 1080x736mm |

Die cutting frame inner size | 1140x750mm |

Max. Paper stacking height of feeding | 1500mm |

Max. Paper stacking height of collecting | 1400mm |

Paper thickness | 80~800gsm cardboard, corrugated board≦4mm |

Min width of waste edge | 8mm |

Max. mechanical speed | 7500s/h (according design arrangement and paper |

Max. Die cutting pressure | 300 Ton |

Air compressor | 0.36m³/min (user prepare) |

Power supply | 380V/50Hz 3 pahse 4 lines, If is other type voltage, user need prepare 25KWA transformer |

Total power | 20kw / 19kw |

Total weight | 16 T /15 T |

Overall dimension | 7300x4250x2350mm / 6350x4250x2350mm |